At Impac Additive 3D we utilize the latest technology in Additive Manufacturing to allow our customers the best looking 3D printed parts, in plastic or metal, at the lowest cost possible. The equipment being used for our process are listed below.

HP MJF 580

Full color 3D Printed parts

Take advantage of engineering-grade thermoplastic for strong parts with full color capabilities.

Materials: PA12 Nylon

Build Size: 13.1″(x), 7.4″(y), 9.7″(z)

HP MJF 5200

High Strength monochrome parts

Produce quality parts while optimizing productivity at the lowest possible cost.

Materials: PA12 Nylon, PA12 Glass Bead Nylon, PA11 Nylon, Ultrasint TPU01, Polypropylene

Build Size: 14.9″(x), 11.1″(y), 14.9″(z)

Desktop Metal Studio System

BMD (Bound Metal Deposition) printing

Printing process that extrudes bound metal rods—similar to how an FFF printer works, while enabling new features like the use of closed-cell infill for lightweight strength.

Materials: 316L SS, 17-4 SS, H13 Tool Steel, Alloy 625, 4140, Copper

Build Size: 11.4″(x), 7.4″(y), 7.7″(z)

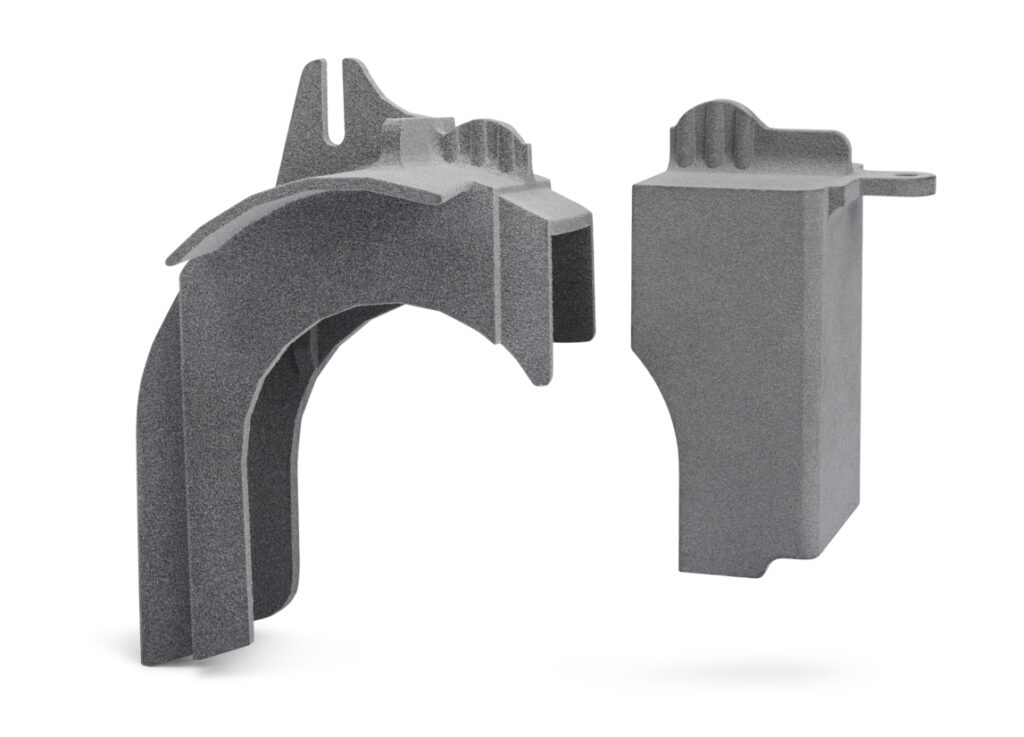

Desktop Metal Shop System

Powder based metal printing

Metal binder jetting system designed specifically to produce parts with exceptional surface finish and resolution at scale.

Materials: 17-4 Stainless Steel

Build Size: 13.8″(x), 8.7″(y), 7.9″(z)

xRize

Augmented Deposition Modeling

Fused Filament Fabrication solution for creating vibrant, full-color functional parts with minimal post-processing.

Materials: Rizium One, Rizium Carbon

Build Size: 12″(x), 8″(y), 8″(z)

AMT De-Powdering System

PostproDP

A speedy de-powdering system, that cleans powder-bed products in just 10 minutes. The machine is equipped with a cyclone, which guarantees that the abrasive is perfectly cleaned.

AMT Smoothing System

Postpro3D

An automated post processing solution for smoothing thermoplastic polymer 3D parts. PostPro3D® achieves an injection molded surface quality on parts printed using Laser Sintering, HP Multi Jet Fusion, High Speed Sintering, or Fused Deposition Modelling technology.